Car engines are complicated beasts with hundreds of moving parts. One of the most recognizable parts by name, though, is a piston.

Although you’ve heard about its importance, you probably can’t explain what it does, right? Let’s walk through a piston’s role inside a car engine and what can go wrong with them.

What Is a Piston?

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders, and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings.

As a part of an engine, the piston converts the energy released during combustion into a mechanical action and transfers it to the crankshaft in the form of a torsional force via a piston rod or connecting rod.

In four-stroke (petrol and diesel) car engines, the intake, compression, combustion, and exhaust process takes place above the piston in the cylinder head, which forces the piston to move up and down (or in and out in a horizontally opposed – or flat – engine) within the cylinder, which causes the crankshaft to turn.

In a pump, the function is reversed, and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder.

Function Of Piston

The piston is a moving part of the combustion chamber. It is responsible for converting the energy released during the combustion process into mechanical work. The piston also performs a number of other important tasks:

- To receive the thrust from the explosion and transmit the force to the crankshaft through the connecting rod.

- Also, it acts as a seal so that the high combustion pressure does not escape to the crankcase.

- To serve as a guide and a bearing for the connecting rod’s small end.

It must also have the following necessary qualities:

- Rigidity to withstand high pressure.

- Lighter in weight to keep its inertia forces to the minimum and enable higher engine speeds.

- Silence in operation both during warming up and normal running.

- Its design should prevent it seizures.

- Its material must have good thermal conductivity for efficient heat transfer. Thus, it reduces the risk of detonation and allows a higher compression ratio.

- Its material should also have low expansion qualities.

- Resist corrosion due to combustion.

- It should be of the shortest possible length to reduce the overall engine size.

- It must have a long service life.

What Are Pistons Made Of?

Engine components today need to be tough for longevity and lightweight to improve efficiency, which means all pistons are some forms of aluminum alloy. But back in the dawn of the horseless carriage era pistons were made of cast iron because they were very long wearing, and resistant to heat that could quickly melt aluminum.

As metallurgy progressed, and temperatures were kept under better control through more efficient design, the lightness of aluminum quickly won out, and allowed much higher RPM to be achieved.

The piston rings continued to be made of cast iron and steel alloys, because of their higher spring constant. The ring package usually comprises, from top to bottom, a compression ring, a wiper ring and an oil ring all made from cast iron or steel.

The compression ring seals the gap between piston and cylinder. The second, wiper ring, contributes to the compression as well as wiping excess oil off the walls of the cylinder as the piston moves downward.

The oil ring is made of 2 rings and a spreader in most motors, and wipes oil from the cylinder wall, then allows it to drain back through small holes in the ring land.

But over time the rings can wear and lose their elasticity, allowing oil from the crankcase to move into the combustion chamber. Excessive oil consumption and bluish smoke from the tailpipes usually indicate piston ring wear.

How Does a Piston Work?

Pistons work by transferring the force output of an expanding gas in the cylinder to a crankshaft, which provides rotational momentum to a flywheel.

In every four-stroke (gasoline or diesel) car engine, the intake, compression, combustion, and exhaust process take place above the crown of the piston, which forces the piston to move up and down within the cylinder.

The piston pushes upward compressing the fuel and air into a much smaller space in the cylinder head, where it is then ignited by the spark plug. The resulting explosion forces the piston downward, creating exhaust gases. A much more complete explanation can be found here.

In any internal combustion engine, the piston performs four roles on each and every cycle.

- First, as the piston goes down, it draws air and fuel into the cylinder or combustion chamber.

- Second, on the upswing, it compresses the air and fuel in the cylinder so it will explode when it ignites.

- Third, the spark plug ignites the air-fuel mixture, and the force flings the piston back down.

- Fourth, the piston comes back to the top of the cylinder, expelling the burnt gases (exhaust) out of the cylinder.

- Then, the cycle repeats over and over, hundreds or thousands of times per minute.

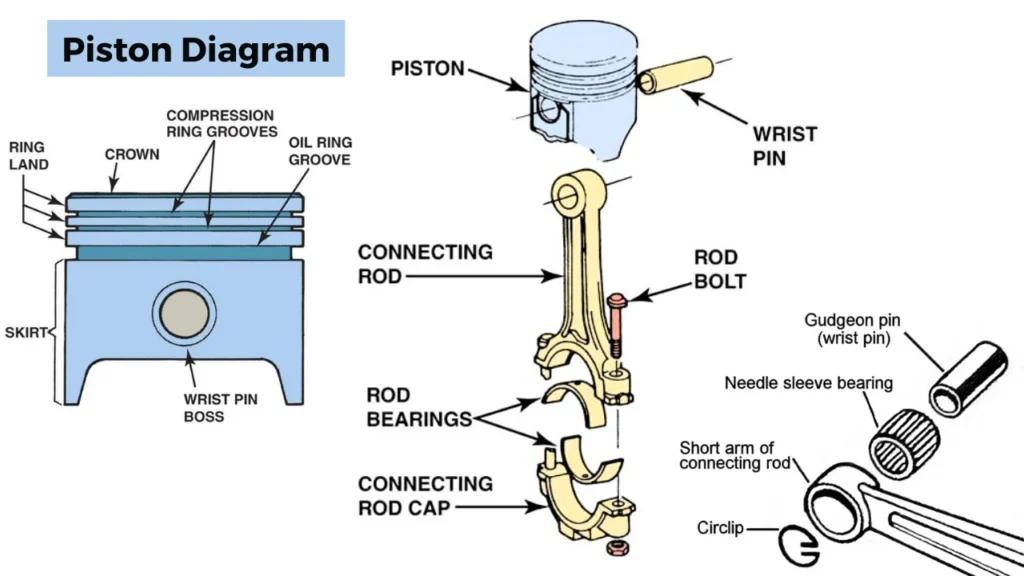

Piston Diagram with Name

Parts Of a Piston

Piston features include the piston head, piston pin bore, piston pin, skirt, ring grooves, ring lands, and piston rings.

1. Piston Ring

A piston ring is an expandable split ring used to provide a seal between the piston the cylinder wall. Piston rings are commonly made from cast iron. Cast iron retains the integrity of its original shape under heat, load, and other dynamic forces.

Piston rings seal the combustion chamber, conduct heat from the piston to the cylinder wall, and return oil to the crankcase. Piston ring size and configuration vary depending on engine design and cylinder material.

Piston rings commonly used on small engines include the compression ring, wiper ring, and oil ring.

- A compression ring is the piston ring located in the ring groove closest to the piston head. The compression ring seals the combustion chamber from any leakage during the combustion process.

- A wiper ring is the piston ring with a tapered face located in the ring groove between the compression ring and the oil ring. The wiper ring is used to further seal the combustion chamber and to wipe the cylinder wall clean of excess oil. Combustion gases that pass by the compression ring are stopped by the wiper ring.

- An oil ring is the piston ring located in the ring groove closest to the crankcase. The oil ring is used to wipe excess oil from the cylinder wall during piston movement. Excess oil is returned through ring openings to the oil reservoir in the engine block. Two-stroke cycle engines do not require oil rings because lubrication is supplied by mixing oil in the gasoline, and an oil reservoir is not required.

2. Piston Skirt

The skirt of a piston refers to the cylindrical material mounted on the round section of a piston. The part is usually made from cast iron material due to its excellent wear resistance and self-lubricating properties.

The skirt contains the grooves to mount the piston oil ring as well as compression rings. Piston skirts come in different styles to suit specific applications.

3. Piston Pin

A piston pin is a hollow shaft that connects the small end of the connecting rod to the piston.

4. Piston Head/Crown

The piston head is the top surface (closest to the cylinder head) of the piston which is subjected to tremendous forces and heat during normal engine operation.

5. Connecting Rod

The connecting rod connects the piston to the crankshaft, and this is functions as a liver arm and transfers motion from the piston to the crankshaft.

The connecting rod is made of cast aluminum alloy. And it is designed in such a way that it can withstand the dynamic stresses of the combustion and piston movement.

6. Connecting Rod Bolt

Also, in the list of piston parts is the conrod bolt. These bolts clamp the rod to the crankshaft. The bottom end of rod bolts bolt are rod caps and bearings, held in place by a nut. A cotter pin on the nut prevents the assembly from coming undone.

7. Piston Bearings

The bearings are piston parts that are located at the points where pivotal rotation takes place. The are usually semicircular metal pieces that fit in the bores of these points. Piston bearings include the shells found at the big end where the rod connects to the crankshaft. There are also bearings at the small end where the rod links to the piston.

Piston bearings are usually manufactured using composite metals like lead copper, silicone aluminum, and others. The bearings are often coated to improve hardness and enable them to bear the load of piston and connecting rod movements.

Types of Pistons

There are three types of pistons, each named for its shape: flat top, dome, and dish.

1. Flat-top Pistons.

As simple as it sounds, a flat-top piston has a flat top. Flat-top pistons have the smallest amount of surface space; this enables them to create the most force. This type of piston is ideal for creating efficient combustion.

Flat-top pistons create the most even flame distribution. The difficulty that comes with this is that it can create too much compression for smaller combustion chambers.

2. Dish Pistons.

This piston type is also known as bowl piston. It features a plate-like shape with raised outer edges. Because of the increased combustion chamber volume, dish pistons achieve a lower compression ratio. Although a drawback, this characteristic is an advantage in some situations where high reciprocating forces are not necessary.

Dish pistons are often used in engines with turbocharged or supercharged combustion. They help to prevent knock or detonation that would be caused by the boosted compression.

In some engines, pistons help to contain the fuel spray, helping to enhance the combustion process. In older engines, the process will be influenced by several factors: piston type, carburetor design, and the volume of the cylinder bore.

3. Dome Pistons.

Domed pistons create a more compact combustion chamber, creating higher compression rates, in theory.

However, domed pistons often create other issues, including slow-burning or incomplete combustion, valve interference, and reduced efficiency. This type of piston should only be used in very specific applications.

5 Things That Go Wrong with Pistons And How To Prevent Them

Pistons in modern engines are built to last but sometimes things can go wrong. These are the most common piston failures:

1. Burned Piston.

A burned piston can be seen instantly once the top of the engine has been removed. You should be able to recognize visible signs of melting and sometimes a burnt hole in the piston. A burned diesel piston is generally caused by dirty fuel injectors being used.

2. Cracked Piston.

Continued usage of low-quality gasoline can lead to cracked pistons. A fractured piston might also be the result of the exhaust gas recirculation system failing. Chip tuning, lack of piston cooling, and a faulty injection nozzle are other possible causes of a cracked piston.

3. Timing belt snapped.

The timing belt plays a key role as it keeps the movement of the pistons and the valves in perfect alternating time. Once the belt has snapped, it can cause a collision between the two which can then lead to further damage.

To prevent the timing belt from snapping, it’s important to change the timing belt according to the car manufacturer’s instructions.

4. Worn piston rings.

Piston rings eventually start to wear and the seal between the piston and cylinder is no longer airtight. As a result, oil makes its way from the crankcase past the piston and into the firing chamber. Symptoms of this are white smoke coming from the tailpipe and a drop in engine oil level.

5. Piston slap.

If the noise doesn’t go away once the engine is up to temperature, the piston or the cylinder could be worn. A noisy piston is caused by too large a gap between the piston and the cylinder wall.